Drone cameras have revolutionized visual inspection by capturing high-resolution images and videos, offering unparalleled insights into infrastructure conditions. These cameras provide detailed asset analysis, uncovering potential weaknesses before they become major problems. Traditional inspection methods often require manual climbing or scaffolding, which can be time-consuming and risky. According to industry statistics, drones can reduce inspection times by up to 50%, drastically cutting costs and minimizing disruption. Additionally, drone cameras can access hazardous or difficult-to-reach areas, ensuring infrastructure integrity without exposing human inspectors to danger, thereby enhancing both safety and efficiency in maintenance practices.

Advanced flight controllers are pivotal for ensuring the precision and stability of drone navigation during inspections. These devices integrate GPS systems and obstacle avoidance features, significantly enhancing the accuracy with which drones can assess infrastructure. By automating navigation, drones can perform consistent and reliable inspections, drastically reducing errors or omissions typical in manual processes. For instance, modern flight controllers have been shown to improve inspection efficiency by up to 30%, as detailed in industry research. This technological advancement not only optimizes time management but also ensures a thorough analysis, hence supporting more effective asset maintenance strategies.

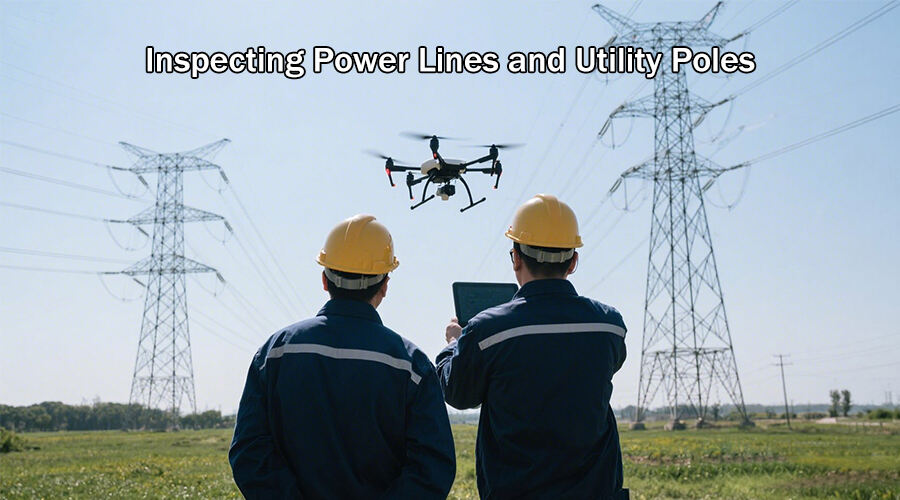

Thermal imaging drones are revolutionizing the way we inspect power lines, offering clear advantages over traditional methods. By using infrared sensors, these drones can quickly identify hotspots and faults in power lines that are invisible to the naked eye. This enables utility companies to pinpoint potential issues before they escalate into serious problems. Studies show that the success rate of fault detection using drones exceeds traditional methods, often reducing inspection times by up to 50%. This not only minimizes downtime but also significantly cuts maintenance costs, allowing for proactive rather than reactive management of power infrastructure systems.

LiDAR mapping technology is transforming bridge and pipeline monitoring by providing precise, detailed measurements of structural integrity. This technology uses laser light to create accurate 3D models, allowing engineers to assess wear and tear or deformation over time. Successful projects, like the one implemented in the Alaska Department of Transportation, demonstrate the effectiveness of LiDAR in evaluating the health of infrastructure accurately. By identifying problems early, interventions can be scheduled timely, prolonging the lifespan of these critical structures and ensuring public safety. This innovation underscores the importance of adopting advanced technologies for infrastructure maintenance.

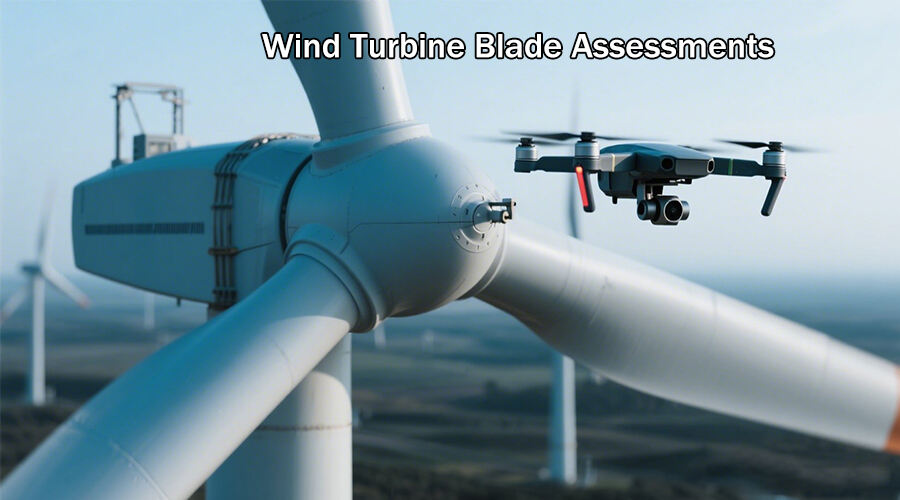

Micro FPV drones have emerged as a game changer in the field of wind turbine blade inspections. These compact drones are adept at detailed assessments, using their agile maneuverability and real-time data transmission capabilities to access hard-to-reach areas of turbine blades. The increased efficiency stems from these drones' ability to transmit data instantaneously, enabling quicker decision-making and reducing turbine downtime. Industry statistics highlight a significant reduction in inspection times compared to conventional methods. This advancement not only shifts the blade assessment process into a higher gear but also underscores the broader potential of drone technology in industrial applications.

The integration of advanced camera stabilizers in drones has become a pivotal factor in capturing clear and stable images during flights. These stabilizers play an essential role in ensuring that images and videos obtained during inspections are free from distortions caused by drone movements. This level of precision enhances the quality of inspection reports, allowing for detailed data analysis and accurate maintenance decisions. Studies have shown that stable and high-quality imaging significantly improves the reliability of inspection findings, directly influencing effective infrastructure management and repair decisions. In essence, camera stabilizers are not just enhancing visual clarity but are vital tools for data-driven maintenance strategies.

Artificial Intelligence (AI) has revolutionized flight control systems in drones, leading to better navigation and obstacle management capabilities. AI-powered systems enable drones to make autonomous decisions, improving their ability to navigate complex environments safely and efficiently. This technological advancement has led to a substantial increase in the safety and reliability of automated inspections. For instance, by utilizing AI algorithms, drones can predict potential obstacles and adjust their flight path accordingly, reducing incident risks. Examples from the commercial sector show that AI-enhanced drones have led to more streamlined operations with improved operational efficiency, demonstrating a clear advantage over traditional manual inspection methods.

Multispectral sensors are transforming the scope of infrastructure inspections by allowing drones to analyze various spectrums beyond the visible range. This capability is particularly valuable in assessing plant health within infrastructure-related environmental projects. By capturing data across different spectrums, multispectral sensors provide insights into vegetation health, soil composition, and water quality, which are critical for projects like bridge construction or environmental restoration. Real-world examples, such as the use of multispectral data in environmental assessments for highway expansions, illustrate how this technology informs decision-making processes, ensuring environmentally sustainable and economically viable project outcomes.

Data security is paramount when using drones for inspections of critical infrastructure. The sensitive nature of the information gathered, such as structural integrity and maintenance needs, requires robust security measures to prevent unauthorized access and data breaches. Advanced encryption technologies and secured data transmission protocols are necessary to safeguard the information collected during drone operations. Cybersecurity experts emphasize that the proliferation of drones in inspections heightens the potential for security vulnerabilities, necessitating ongoing efforts in data protection strategies. Ensuring the integrity and confidentiality of inspection data not only protects the infrastructure but also maintains trust and compliance with industry standards.

Predictive analytics, powered by drone-collected data, represents a transformative approach for forecasting infrastructure maintenance needs. These drones, equipped with advanced sensors, gather extensive data that can be analyzed to predict potential issues before they occur. For example, using metrics such as temperature changes or structural shifts, analytics software can anticipate wear and tear, thereby enabling preemptive maintenance actions. A case study from a bridge maintenance program revealed that employing predictive analytics led to a 20% reduction in operational costs and increased infrastructure longevity by identifying issues early. Consequently, integrating predictive analytics with drone technology can significantly enhance asset management and reduce long-term maintenance expenses.

Swarm technology introduces an innovative solution for conducting large-scale inspections by deploying coordinated drone networks simultaneously. This approach allows multiple drones to work together, efficiently covering vast infrastructure areas, such as pipelines or power grids, in a fraction of the time required by single-drone operations. By leveraging advanced algorithms for flight control, these drone networks optimize their paths to avoid overlap and maximize coverage. Studies have shown that swarm technology can improve inspection times by up to 40% and provide high-resolution imaging essential for accurate assessments. Pilot programs have successfully demonstrated the superior efficiency of coordinated drone inspections in terms of speed and data reliability, paving the way for widespread adoption in infrastructure maintenance.

The development of autonomous repair drones is pushing the boundaries of technological innovation, enabling repairs without human intervention. These drones are equipped with specialized tools and artificial intelligence to perform precise repairs, such as sealing or welding, on infrastructure components. Industries including wind energy and telecommunications stand to benefit significantly from these advancements, as the drones can autonomously handle repair tasks in remote or hazardous environments. Experts predict that within five years, autonomous repair drones will become widely operative, potentially revolutionizing the maintenance industry by dramatically reducing repair costs and minimizing safety risks associated with manual intervention. Such innovations promise to enhance efficiency and reliability across various sectors, ushering in a new era of proactive maintenance strategies.

Hot News

Hot News