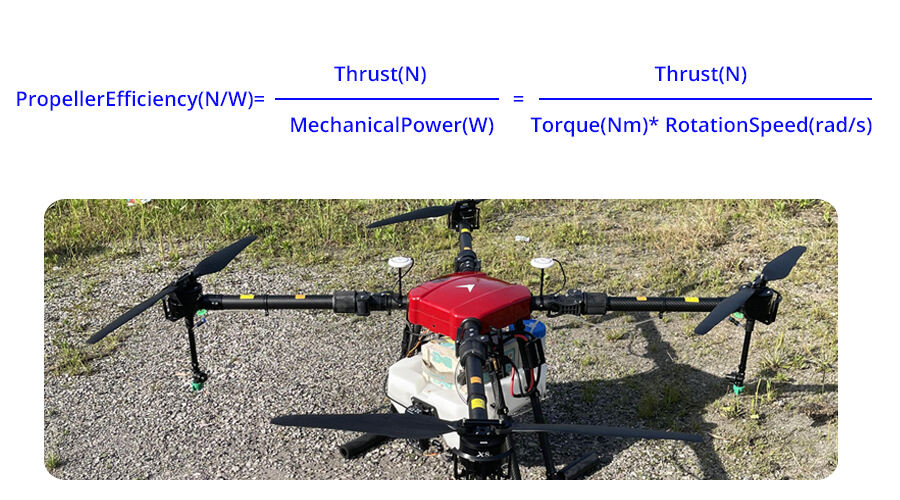

Understanding the payload capacity in sprayer drones is crucial for balancing stability and efficiency. Payload capacity refers to the maximum weight a drone can carry while maintaining flight stability, which is vital for efficient agricultural operations. The key metric here is the thrust-to-weight ratio, which determines how much lift a drone can generate in relation to its payload. For instance, a higher thrust-to-weight ratio allows a drone to carry heavier liquid payloads necessary for spraying operations without compromising flight performance. Typically, agricultural drones, especially those used for spraying fertilizers or pesticides, have payload capacities ranging from 10 to 30 kilograms, which makes them suitable for medium to large-scale farming tasks. This balance ensures that drones remain agile and efficient while performing their tasks.

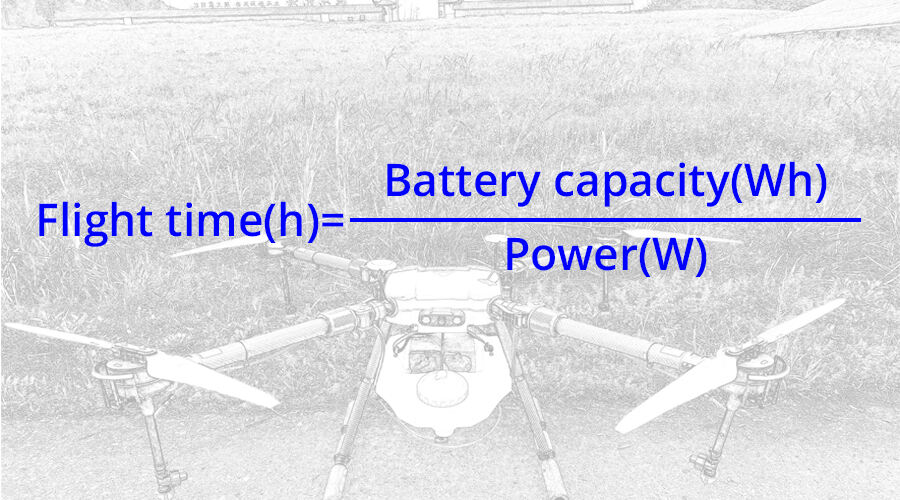

The flight time of agricultural drones is significantly impacted by the weight of spraying loads, such as liquid fertilizers and pesticides. As payload increases, the energy required to maintain flight stability rises, reducing the drone's overall flight time. According to analysis, a heavier payload results in greater battery consumption because the drone must work harder to remain airborne. For example, studies have demonstrated that adding a payload can diminish a drone's flight duration by up to 30%. Therefore, understanding the energy consumption dynamics when transporting heavier loads is crucial for efficient agricultural planning. Operators need to strategically plan their operations, considering both payload weight and battery life, to maximize flight time, reduce downtime, and enhance overall productivity.

There is a delicate engineering trade-off between tank size for liquid payloads and the resultant impact on battery efficiency in agriculture drones. Larger tanks accommodate more chemicals, allowing drones to cover larger areas without refilling, but they also increase the drone's weight, leading to higher battery drain. To counteract these challenges, manufacturers have introduced various engineering solutions. One approach is modular design, allowing tanks and batteries to be swapped quickly to maintain efficiency. Leading drone manufacturers often use examples from industry professionals who successfully balance these elements, optimizing both tank size and power consumption. These strategies not only maintain flight duration but also enhance the effectiveness of spraying operations.

The efficiency of agriculture drones is highly dependent on the battery capacity-to-payload weight ratio. This ratio directly influences how long a drone can operate effectively, as a heavier payload demands more energy, thereby reducing flight time. Industry standards suggest that an optimal ratio involves balancing battery advancements with payload demands to avoid frequent recharges, which can disrupt operations. Empirical data show that drones operating with a 6S or 12S battery system demonstrate differing performance metrics based on payload ratios. For instance, a higher energy density battery like those used in mPower 12S 21000mAh systems can sustain longer flights even with heavy agricultural loads, thereby optimizing field productivity.

Aerodynamic design is crucial in boosting sprayer drones' maneuverability and stability during crop spraying. Key components include wing shape and frame material, which are pivotal in enhancing flight performance. According to aerodynamic studies, drones with streamlined frames and optimal wing configurations encounter less air resistance, thereby conserving energy and allowing longer flight durations. For example, expert reviews emphasize that the use of carbon fiber materials can significantly reduce the weight while maintaining structural integrity. This design optimization ensures drones can handle the turbulence and diverse terrains typical of agricultural environments efficiently.

Multi-axis design refers to drones engineered with multiple rotors that facilitate improved stability and flexibility during agricultural tasks. This design maximizes operational efficiency by offering superior control, which is crucial for precision spraying. Statistics indicate that multi-axis drones show enhanced performance metrics, with improved payload handling and extended flight durations as compared to single-axis counterparts. However, there are trade-offs in complexity and maintenance; multi-axis systems often require more sophisticated repairs and calibration. Still, the benefits such as agility and operational precision in crop spraying make the investment worthwhile in high-demand agricultural scenarios.

Smart payload distribution is crucial for balancing and maintaining the aerodynamics of agriculture drones during flight. Innovative strategies, such as adjustable payload compartments, ensure that the drone's center of gravity is optimized, leading to more stable flights. Technology like real-time load monitoring allows drones to adjust their balance dynamically, improving flight efficiency. For instance, a case study on the use of such smart systems showed improvements in flight times and overall area coverage due to better weight distribution. This kind of technology not only optimizes sprayer drone performance but also enhances operational longevity.

The integration of flight path algorithms is a pivotal strategy in optimizing drone operations for energy efficiency and greater field coverage. By employing algorithms that optimize the flight paths, drones can minimize unnecessary flight maneuvers, subsequently reducing energy consumption. AI integration enhances this further by considering real-time environmental conditions to adjust paths for optimal coverage. A study showcasing the benefits of strategic flight pathing highlighted a significant reduction in energy usage, underscoring AI's transformative role in agriculture drone applications. These advancements make agriculture drone spraying more sustainable and cost-effective, crucial in today's climate-focused agricultural practices.

Essential maintenance practices are vital to preserving battery longevity, ensuring that agriculture drones can perform optimally over extended periods. This includes proper cycle management, such as avoiding deep discharges and maintaining a 40-60% charge during storage. Environmental considerations, like operating within safe temperature ranges and avoiding extreme conditions, also matter. Expert guidelines emphasize regular battery checks to preemptively identify issues. Statistics reveal that consistent adherence to these practices can extend battery life significantly, highlighting the importance of meticulous care in drone operations. These steps are integral to maximizing drone uptime and minimizing operational costs in agricultural settings.

The 4-Axis 10L drone stands out for its lightweight and agile design, making it an ideal choice for small and medium-sized farms. Designed for ease of maneuverability, it allows farmers to effectively manage crop spraying tasks in limited spaces. This model's compatibility with various spraying systems enhances its versatility across different crop types, providing tailored solutions for diverse agricultural needs. User feedback consistently highlights its agility and user-friendliness, even in complex environments.

The 6-Axis 16L model is designed for mid-sized agricultural operations, offering a fine balance between payload capacity and operational stability. Professionals in agriculture have praised its performance in challenging conditions, attributing its robust stability to advanced design and weight distribution technologies. Such advancements contribute to its ability to maintain steady flight and effective spraying, even in adverse weather conditions.

For large-scale agricultural operations, the 6-Axis 30L Heavy Lifter drone provides a robust solution with its high-capacity tank. This model is emphasized for its ease of use and efficient design, which includes advanced payload management technology that supports substantial volumes of spray with maximum coverage. Statistics highlight its cost-effectiveness by reducing the need for multiple smaller drones and increasing operation efficiency in expansive fields.

The design of the 8-Axis 16L drone focuses on providing precision spraying capabilities in diverse terrains. Farmers have noted its operational flexibility, with the ability to perform real-time adjustments during flights, thus ensuring accurate coverage irrespective of landscape irregularities. Its technology allows for seamless control, maximizing crop coverage while minimizing wasted resources, particularly in undulating terrains.

Geared towards industrial-scale agriculture, the 8-Axis 20L drone excels in covering large fields efficiently. Its features cater to extensive operations with performance metrics showcasing significant coverage. Testimonials indicate its effectiveness in maximizing field productivity through high-efficiency spraying systems.

The integration of IoT sensors in agriculture drones has transformed the way spraying is conducted, by allowing real-time payload adjustments during flight. This enhancement increases the precision and accuracy of drone spraying, catering to dynamic agriculture environments. Case studies have highlighted the significant benefits IoT brings to drone operations, including seamless adjustments to payload to match varying field conditions. Looking forward, advancements in IoT applications will potentially expand these capabilities to encompass predictive maintenance and more refined data analytics, further revolutionizing agriculture practices.

Hybrid battery systems combine the strengths of different battery technologies to enable longer mission durations for agriculture drones. By integrating lithium-ion and other emerging battery types like fuel cells, these systems provide a balanced power supply that enhances drone flight time. While the primary advantage of hybrid systems is their ability to extend operational times, there are considerations regarding weight and complexity that need careful evaluation. Industry reports suggest a growing adoption rate of these systems, with users generally satisfied with the extended operational benefits, albeit some concerns about initial costs and system management.

AI algorithms have revolutionized flight optimization in agriculture drones, ensuring efficient and comprehensive spray coverage. Through machine learning techniques, drones can determine the most efficient flight paths, reducing overlaps and optimizing resources. Real-world applications illustrate the benefits of AI, such as increased crop yield and reduced chemical usage, with research indicating a 20% improvement in efficiency compared to traditional methods. As AI technology continues to evolve, it is anticipated that future integration will include more autonomous decision-making capabilities, enabling drones to adapt intelligently to real-time field conditions.

Hot News

Hot News