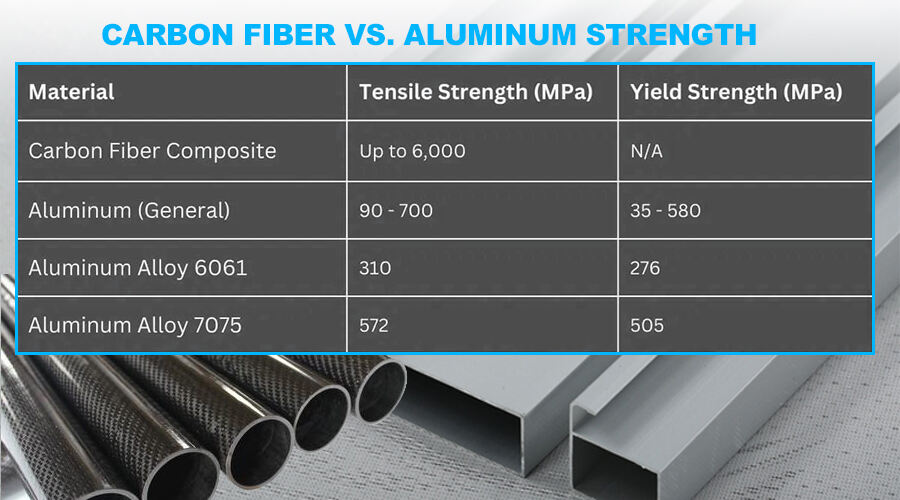

Carbon fiber stands out with a tensile strength between 3500 to 6000 MPa, significantly surpassing aluminum alloys, which usually range from 300 to 700 MPa. This distinction ensures greater structural integrity in drone frames. The superior tensile strength allows carbon fiber frames to withstand substantial forces during flight, culminating in enhanced durability and safety. Studies consistently show carbon fiber structures exhibit less deformation than aluminum under equivalent loads, a critical factor in maintaining optimal flight performance.

Carbon fiber is renowned for being lighter than aluminum, which fundamentally reduces the drone frame's overall weight to bolster flight efficiency. A lighter frame strategically allows for extended flight durations and accommodates additional payload, making carbon fiber a preferred choice for racing drones. Industry reports have suggested that reducing frame weight by merely 10% can elevate flight efficiency by up to 20%, underscoring its significance in optimizing drone design.

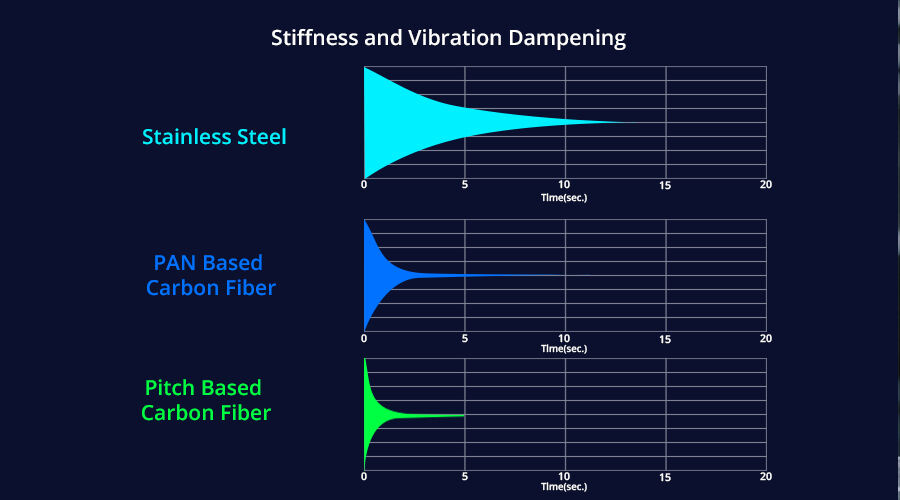

Carbon fiber offers superior stiffness compared to aluminum, profoundly impacting the drone's responsiveness and agility during intricate maneuvers. Its exceptional vibration dampening qualities significantly minimize interference with onboard sensors and motors, thereby improving overall performance. Expert insights highlight that reducing vibrations is vital for applications demanding extreme stability and sensitive data collection, making carbon fiber indispensable in advancing drone technology.

Carbon fiber frames are renowned for their exceptional impact resistance due to their energy-absorbing properties, making them more durable in collisions. When drones collide or fall, carbon fiber's ability to withstand high-energy impacts prevents the frame from cracking or splintering, unlike traditional materials. In crash tests, drones equipped with carbon fiber frames consistently show less damage compared to those made with aluminum, which often dent or deform significantly. This robustness is supported by statistical data indicating higher survival rates for drones utilizing carbon fiber materials upon impact, making them ideal for rugged and demanding applications.

Carbon fiber inherently offers superior corrosion resistance compared to aluminum, which often requires protective coatings to prevent oxidation, especially in harsh conditions. The structural integrity of aluminum drones can suffer without these coatings, leading to increased maintenance costs and frequent repairs. In contrast, research shows that carbon fiber drones perform reliably in environments with high moisture or salt exposure, such as coastal areas, which underscores their suitability for operations in challenging environmental conditions. This resilience not only enhances drone longevity but reduces operational downtime and upkeep expenses.

A notable advantage of carbon fiber is its non-interference with radio frequency (RF) signals, offering seamless signal transparency crucial for drone communication systems. Aluminum frames, on the other hand, can reflect or attenuate RF signals, potentially causing a loss of communication or control during flight operations. Technical studies have demonstrated that drones with carbon fiber frames maintain better connectivity, which is essential for remote and autonomous operations. This consistency in communication ensures reliability, especially in applications where precise control is warranted, such as aerial photography or surveillance.

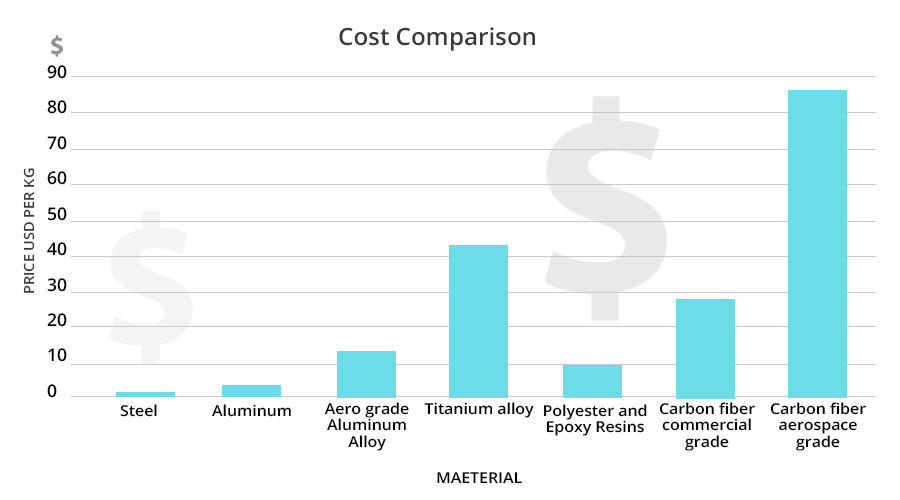

Carbon fiber layup techniques significantly impact the strength and weight of drone frames. Methods such as vacuum bagging and resin infusion produce high-quality parts with enhanced structural integrity and consistency. However, these processes are meticulous and time-consuming, which can increase production costs. The high cost of raw carbon fiber materials and the complexities involved in their processing may deter hobbyists but offer worthwhile long-term performance benefits for professional drone applications, as they contribute to the lightweighting strategy that improves flight efficiency.

Aluminum alloys present significant advantages in drone manufacturing due to their simpler machining requirements. Utilizing CNC technology, these alloys can be crafted with high precision, minimizing waste and optimizing material use. Their cost-effectiveness is paired with wide availability, making them accessible for hobbyists and small-scale manufacturers particularly focused on budget constraints. Aluminum's machinability is instrumental in the production of drone frames, offering an efficient balance between durability and cost.

When evaluating budget considerations, hobbyists usually opt for aluminum due to its affordability and ease of use, allowing them to craft simpler designs. In contrast, professionals tend to invest in more costly materials like carbon fiber, leveraging its superior performance benefits. Understanding the correlation between production costs and intended use is important for both groups. While hobbyists focus on cost-saving measures, professionals often prioritize performance, reflecting consumer surveys that point towards a preference for high-end materials despite higher initial costs.

The TYI 13-Inch DIY FPV Racing Frame stands out for its durability and lightweight design, traits that make it a favorite among FPV (First Person View) drone racing enthusiasts. Constructed from high-quality carbon fiber, it promises to deliver exceptional performance in competitive environments. Users often praise this frame for its ease of assembly and customizable features, allowing pilots to tailor the setup to their specific racing preferences.

The Tarot T18 Aerial Photography Frame is meticulously engineered to ensure stability and smooth aerodynamics, making it an excellent choice for high-quality aerial photography. The carbon fiber construction effectively minimizes vibrations, which is vital for capturing clear and stable images and videos. Users frequently commend its ability to handle substantial payloads, allowing it to support various camera systems efficiently.

The SpeedyBee Bee35 Frame excels in its compact design, offering great versatility across various flight conditions while maintaining high performance. Crafted from durable carbon fiber, it offers a lightweight yet robust frame that suits both amateur and professional drone pilots. Additionally, its compact nature is widely praised for facilitating easier transport and setup, a desirable feature for those who frequently travel with their drones.

Selecting the right material for a drone is crucial, as it directly impacts the performance and application of the drone. Racing drones prioritize speed and maneuverability, often opting for materials like carbon fiber for its lightweight and strong characteristics. On the other hand, commercial UAVs typically require durability and the ability to carry heavier payloads, where options such as aluminum offer a more budget-friendly solution. Choosing the appropriate material can significantly affect a drone's success. Studies show that the correct frame material choice enhances reliability and performance, tailoring the drone for its specific use.

When considering drone materials, factors like repair costs and maintenance frequency play a vital role. Although carbon fiber frames might have a higher initial cost, their robustness often leads to fewer repairs and lower long-term upkeep. Carbon fiber's durability can result in prolonged intervals between repairs. In contrast, aluminum may endure wear and tear more readily, increasing maintenance and replacement costs. Investing in carbon fiber can lead to significant savings over a drone's lifetime by reducing the need for frequent repairs, as experts often recommend prioritizing long-term profitability over upfront cost-effectiveness.

Investing in advanced materials like carbon fiber is a proactive approach to future-proofing your drone assets. With technology and performance standards evolving rapidly, selecting high-performance materials now can offer a competitive edge in the future. As drones increasingly serve various commercial applications, having a drone constructed with advanced materials ensures durability conforms to rising standards. Industry forecasts indicate that as technology advances, opting for drones built with superior materials will become integral to maintaining their relevance and effectiveness in various operations.

Hot News

Hot News